Our Application configurator provides a large number of standardized, configurable software modules. It makes the process of configuring basic single-access application modules and complex multi-axis application modules significantly easier, and completely dispenses with the need for programming.

Configure rather than program, using our CCU (Configurable control unit)

- Single-axis application modules: Configurable software modules for controlling single axes in various operating modes such as speed control, positioning, and phase-synchronous operation.

- Multi-axis application modules: Configurable software modules for controlling complex motion sequences for stacker cranes, winding applications, and kinematic applications, for example.

Get in touch with us.

- Our experts understand your industry and requirements.

- Our global network ensures we are there wherever and whenever you need us.

- We have the expertise and the tools to provide optimum advice and support.

Your benefits

-

Configure rather than program

Graphical configurators allow you to configure predefined application and technology modules that can be run directly -

Smooth startup

Our standardized application modules allow for quick startup, without the need for time-consuming programming -

Optimize your applications

We provide a wide range of diagnostics tools for optimizing your applications

Features

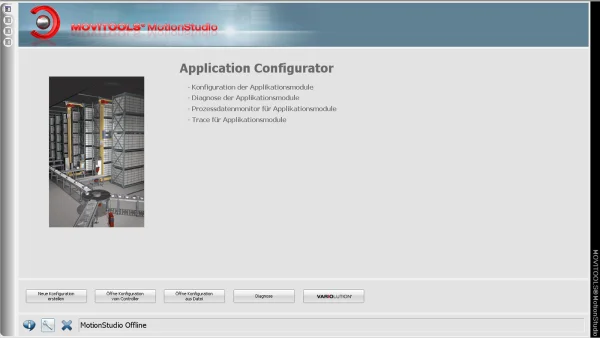

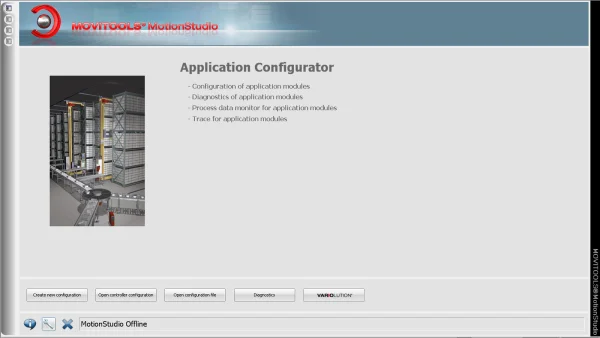

Configure applications quickly and easily using our Application Configurator for CCUs

- Graphical configuration of modules via PC

- Standardized single-axis and multiple-axis application modules can be configured and run directly

- Modules can be controlled via a standardized process data interface

- A special control mode allows for pre-startup, without the need for a higher-level PLC (programmable logic controller)

- Shorter response times when coordinating multiple axes

- Integrated diagnostics make startup quicker and smoother

Application modules

Standardized application modules for common positioning and motion sequences that can be run directly

Single-axis application modules

- Speed control

- Universal module: Speed, positioning, modulo, remaining distance

- Universal module technology, with phase-synchronous operation

- Rapid/creep speed positioning

Multi-axis application modules

- HandlingKinematics: Implementation of kinematic and handling applications

- effiSRS: Energy-optimized coordination of drive and hoist axes for stacker cranes

- Winding systems: For effortless winding and unwinding of materials

- SyncCrane: For easy control of crane bridges and lifts

Universal module

Standardized application modules for common positioning and motion sequences that can be run directly

Benefits

- Positioning type can be configured in linear or modulo mode

- Positions specified as absolute or relative positions

- Speed synchronization with configurable master value sources

- Four process data profiles (4, 6, 7, 10 PD)

Universal module technology

Expand the functional scope of the universal module with additional angle-synchronous applications

Benefits

- Synchronous movements by up to 8 drives in one master-slave combination

- Distance-based or time-based synchronization

- Configurable offset during synchronous travel

Application module for rapid/creep positioning

Implement cost-effective transport solutions, for example

Benefits

- Easier to compare disturbances caused by slippage, for example, and to set the required position by moving a sensor

- Drive functionality: Jogging and positioning

- Suited for roller conveyors, lifting tables, and rotary tables

HandlingKinematics application module

Easy configuration of pick-and-place applications

Features

- The HandlingKinematics application module supports quick and easy startup of kinematic and handling applications thanks to its intuitive software and graphical configuration interface. This module allows a significant reduction in cycle time thanks to configurable S-ramps and contour-accurate path control with integrated look-ahead functionality.

Benefits

- Fieldbus interface with up to 20 path points and configurable wait points for each path segment

- Touch probe measurement function and sensor-based positioning

- 3D simulation for startup and diagnostics

effiSRS application module for energy-efficient stacker cranes

Support energy-efficient operation of high-bay warehouses in the long term

Benefits

- Energy-efficient coordination of vertical lifting and horizontal travel axes

- Support for one or two vertical lifting drives

- Slackness detection, buffer storage, optional recovery

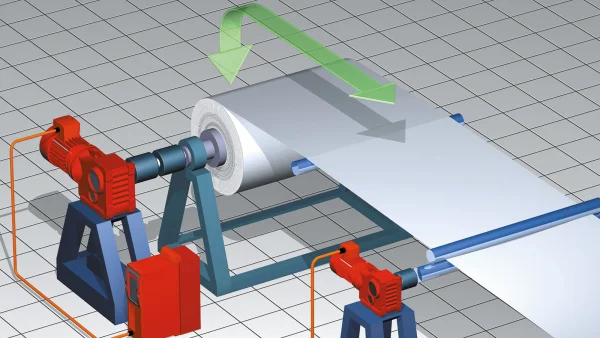

Winder application module

Wind and unwind material at a constant tension or line speed

Features

- Designed for applications that require the winding or unwinding of material based on a constant tension or line speed

- Different winding technologies for different materials and machine situations

Benefits

- Tension determined by winder via torque control, tension control, and jockey position adjustment

- Speed determined by winder with optional speed control